IFSJ Exclusive: Beyond the foam with Fomtec

- January 11, 2023

- 9:01 am

Iain Hoey

Share this content

John Olav-Ottesen, Managing Director and Founder at Dafo Fomtec AB, explains why the transition to synthetic fluorine free foam is about more than just the foam

Legislation continues at a pace such that our industry talks everyday about the transition away from PFAS containing foam. For end users and specifiers, the obvious question is: “What foam should I choose”. Ignoring price and focussing on performance this is still difficult because SFFF (Synthetic Fluorine Free Foam) is still an emerging technology. Internationally recognised approvals are a good place to start but there are other variables to be considered and some are not down to the chemical formulation of the foam concentrate alone.

Whether looking at a new project or considering making the transition away from a PFAS containing foam it is necessary to consider several factors and variables into the decision on the most appropriate firefighting foam to use. Some of these factors are dependent on the location of the hazard, the type of hazard, the fuels involved, and the standards and international approvals requested on the foam.

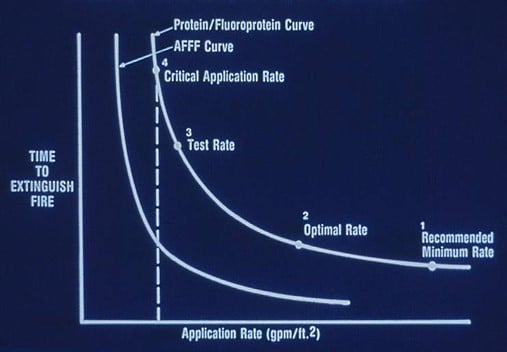

Figure 1 dates back 30 years to when I started in the foam business and illustrates one of the fundamental basics relating to the use of foam, which is there is an amount of foam that must be applied to a Class B fuel fire before it will extinguish. If we then increase the application density the extinguishing time decreases.

Test data over 50 years with PFAS containing foams allowed organisations such as UL, FM and EN to establish test rates and then advise on recommended minimum application rates. It is worth noting that the figure also shows that even 30 years ago we recognised that non film forming foams performed differently to our AFFF’s, FFFP’s and their AR versions.

The figure however still does not address the variables we see in real world missions, but as SFFF is non-film forming it is a reasonable assumption that the curve for an SFFF would be similar to that of the protein/fluoroprotein curve.

Considering the variables that could impact the curves we must start with the foams from different manufacturers and here it could be argued that a test protocol such as EN 1568-3 and EN 1568-4 is a suitable test protocol for this comparison as the only variables involved are the foam concentrate used and the foam qualities achieved with the foam solution through the UNI 86 nozzle.

This is conversely one of the weaknesses with this particular test protocol as the UNI 86 nozzle is a test nozzle and foam qualities achieved with discharge devices used in the field maybe very different, leading to different extinguishing times and reflash protection.

There is a strong argument therefore that different expansion ratios should be considered as part of the EN 1568-3 and EN 1568-4 test protocols, but this variable alone ignores the 25% drain time. Both UL 162 and FM 5130 consider a range of expansion ratio and 25% drain time when testing top side fire performance of a foam, and these must be matches to achieving those foam qualities based the operating parameters of a defined discharge device.

Discharge devices

The link between the foam concentrate and the discharge devices is even stronger when considering standard sprinklers as the discharge device. Here the EN approach is currently to ask the manufacturer for recommendations without giving any additional guidance on what data an end user or specifier should request. UL and FM, and now VdS now have test protocols using the heads that will upon successful testing be approved with the tested foam concentrate.

The impact of different fuels with SFFF’s has been discussed for some time and testing has been carried out by a number of organisations such as NRL, NFPA Research Group, and LASTFIRE. As a result of some of these tests we have already seen from the May 2021 edition of NFPA 5130 that under section 4.2 – Low Expansion Foam Concentrate Extinguishing Performance, within section 4.2.2.3 it states:

“When testing SFFF concentrates, Heptane is considered representative of hydrocarbon liquids with the following characteristics:

- Flash point equal to, or greater than, Heptane.

- Vapour pressure equal to, or less than, Heptance

- Pure liquids (i.e. not blended such as gasoline / alcohol combinations”

Wording in FM approvals has been changed such that approvals now state “heptane” rather than “hydrocarbons”. At Fomtec we see on a weekly basis lists of chemicals being submitted with the questions asked about what application densities should be used for these chemicals. In many cases we just don’t have the test data with those chemicals so are having to advise our clients when what we are responding is “an opinion”.

For emergency response and the fire and rescue services the situation with some many different fuels and different discharge devices does see a tendency to favour use of following an EN 1568-3 and EN 1568-4 based analysis. As stated previously, hand lines are not equipped with UNI 86 test nozzles and typically a foam/water hand line nozzle will generate lower expansion and 25% drain times than that achieved with the test nozzle suggesting that greater application densities (and hence greater flow rates) will be required than should be indicated in the test.

Testing protocols

Operator techniques will also impact firefighting performance. Now test protocol exists to prove this in a quantitative way but the reports from the NFPA Research Group, and the FAA following their evaluation testing of SFFF’s both reported that their test engineers developed different operation techniques and improved extinguishing times.

It is clear from the more than 1500 fire tests that Fomtec has carried out, and supported by test data from third party organisations mentioned that the variables of fuel, foam qualities, application density and operator experience/techniques all contribute to the performance of the foam. Whilst finished foam qualities are partly due to the foam concentrate they are also due to the discharge devices and small changes with the discharge device can have a significant impact on the fire performance of the finished foam.

Extrapolation of data to predict the performance of foam if a variable is changed means giving an opinion and of course as soon as a different product, whether manufactured by Fomtec, or by another manufacturer, is introduced into the evaluation then the potential for a larger error with the opinion is greater.

Returning to our figure of extinguishing time versus application density it is clear that if operational application densities are required we must also take into account how these curves vary when the variables change. Here at Fomtec we are committed to our test programme called “The Enviro Programme” to establish the limits of performance for our SFFF products as the variables are changed, as decisions need to be based on Data, rather than opinions.

Boxout—

The list provided below is NOT exhaustive but the variables more directly relating to the fire performance of the SFFF concentrate are covered:

| SFFF Foam Concentrate | |

| What type of foam | Suitable for hydrocarbon fuels or hydrocarbon + water miscible fuels. |

| Proportioning ratio | Typically 1%, 3% or 6% but can be different ratios of foam concentrate to water to generate the foam solution. |

| Expansion ratio of finished foam | Suitable for LOW, MEDIUM or HIGH Expansion finished foam? |

| International Listings / Approvals | What listings/approvals does the foam hold and are these appropriate for the application/mission. |

| Testing / Approvals with discharge devices | Provides confirmation that fire performance has been achieved with finished foam produced with the discharge device. |

| Testing / Approvals with fuels in hazard | Different fuels even within group types can require different application densities. |

| Testing / Approvals with type II and type III application | Emergency response with handlines or monitor response should use foam concentrates with type III listing / approval on hydrocarbon fuels. |

| Compatibility with dry chemical | Limited data available in impact of dry chemicals onto SFFF foam blankets. |

| Hardware | |

| Material compatibility | Consult manufacturers technical data to confirm that storage tanks and transfer pipework etc is suitable for the foam concentrate and solution. |

| Proportioning equipment compatibility | Has the proportioning equipment been tested / approved with the foam concentrate. |

| Discharge devices | What testing / approvals are available with the foam. Are there constraints on pressures and flow rates? |

| Operator Related | |

| Training in use of discharge devices – handline + nozzles, monitors | Best mission performance will require training in the use of equipment with SFFF’s |

| Knowledge of tested and approved foam qualities | Optimum performance in manual firefighting will require knowledge of the foam qualities from the discharge devices. |

This article was originally published in the January edition of IFSJ. To read your FREE digital copy, click here.