IFSJ Exclusive: The Evolution of Fire Detection with GFE

- April 11, 2023

- 8:57 am

Iain Hoey

Share this content

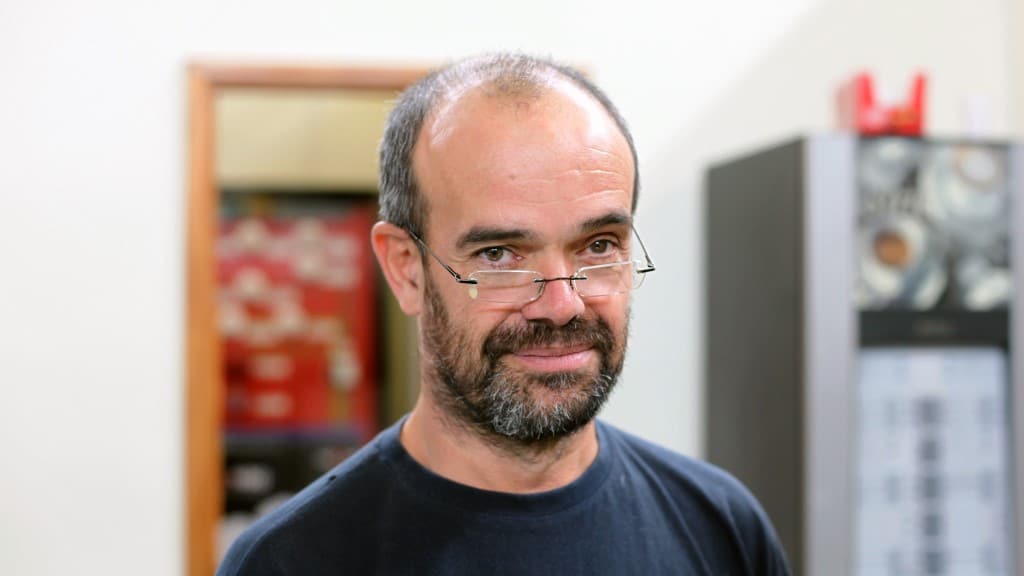

João Paulo Ajami, Managing Director and Founder at Global Fire Equipment (GFE), talks about the evolution of the fire detection company

How did you get started in the fire industry?

I first became interested in electronics when I was around 12. By the time I was 20 (in 1977), I started working in the electronics lab of a security company, working in repairs and development. In 1983, I launched my first company – a security manufacturing company – where we produced control panels for intrusion alarms. By 1986, we were supplying most of the security companies in Portugal before I sold the company.

I moved into fire detection through a collaboration between the company I was working for in Lisbon and I.A.S. Electronics in the early 1990s. Our plan was to establish a joint venture to manufacture fire alarm control panels in Lisbon. That fell through but I was then invited to move to England and help I.A.S. develop a new range of products. I stayed there until Spring 1993 when I moved to Denmark with my Danish fiancée.

In 1994, I established Global Fire Equipment, known as I.A.S. Denmark at that time. In 1998, the parent company I.A.S. Electronics was acquired, and our collaboration was left in limbo. I decided it was time to branch out on our own.

Why did you make the move to Portugal?

By 2000, we were doing a lot more manufacturing and needed to relocate to somewhere where it would be more cost effective to operate. I decided to move the company to Portugal – being Portuguese it was a natural move. Right from the beginning we opted to base the company in the Algarve. The quality of life in the south of Portugal is far better than in Lisbon. We were also in a place where there is very little other industry in terms of manufacturing which put us in a good position in terms of finding and retaining labour resources.

The fire safety sector is constantly evolving – how do you stay agile?

We keep re-inventing ourselves. The big difference between GFE and most of our competitors is that we are technology driven rather than commercially driven. We understand the importance of innovating and developing new products. We also understand that you always need to listen to customers – old and new – to understand the challenges they face. This is what sets GFE apart from our competition.

The challenging part is being able to continually innovate and deliver what the customers ask of us within their regulatory framework. We ensure that everything we do always conforms to the requirements of each customer’s regional regulation.

What different requirements are there in different regions and how you work to meet these?

The most important thing is listening to our customers. The big advantage we have against the larger corporations is that we work across more than 90 countries worldwide. This means we are fully versed in the differing requirements in countries all over the world.

What did you learn from working with them?

Well of course you need to understand the different legal systems. For example, in an unregulated market like Brazil almost anything goes. So, we spend a lot of time helping educate them so they understand that they are protecting lives and should pay attention to what the system is doing.

In comparison, our Scandinavian customers demand exceptionally high levels of functionality and reliability. There is a wide range of requirements, and we listen to all of them. It’s not easy, but it is a necessity and can be rewarding.

What are GFE’s biggest milestones as a company so far?

When we moved to the Algarve, we had been active for six years and we moved into a 200sq m facility. Seven years later, we moved to an industrial park where we had an 800sqm facility. In 2013, we moved again to an old mushroom canning facility that was 3,400sq m and at the start of 2023 we moved into a new estate converted from a cork transformation factory, which spans around 7,500 Sq m, with the option to expand up to 16,000sq m.

From a technology and staff point of view, we went from mainly supplying control panels to making our own range of sensors back in 2012. We decided we needed to have our own manufacturing facilities for everything in the fire detection system, so we parted with our detector supplier and designed and started making our own. This was the biggest milestone because it meant increasing our manufacturing by more than 60%. Today, we have a state-of-the art manufacturing facility and are able to cope with anything that is thrown at us.

What is GFE’s main focus for the years ahead?

Our goal is to strengthen our production capability – that is 100% necessary. We are looking to increase our autonomy and go into metal working because that’s the only thing we don’t do in-house currently.

Back in 2018, we acquired Createch, a company from the North of Portugal that specialises in emergency lighting. They were operating exclusively in Portugal and are the number two player in Portugal in their field. It’s an exciting opportunity that’s very much on the horizon but for now we are focused in growing the core fire safety business in new regions around the world.

This article was originally published in the April edition of IFSJ. To read your FREE digital copy, click here.