IFSJ Exclusive: A safer approach to wind-driven fires with Cold Cut Systems

- November 28, 2022

- 8:00 am

Iain Hoey

Share this content

Bernie Higgins, Head of Strategic Business Development at Cold Cut Systems UK, discusses a safer approach to wind-driven fires

Many of you will have seen, either in person or online, a demonstration of Cobra Ultra High Pressure Lance (UHPL) firefighting equipment. These demonstrations were usually undertaken using fire behaviour containers with a time and temperature indicator clearly visible, this enabled observers to see how quickly the temperature within the container dropped. This type of demonstration emphasised the value of using the Cobra Method also known as SAVE Scan Attack Ventilate Enter involving use of a Thermal Imaging Camera to scan, use of Cobra to cool and use of a Positive Pressure Ventilation – PPV – fan to clear away the residual steam and fire gases. This enables firefighting crews to gain safe access to a compartment fire.

It is also a very useful method for showing how Cobra works and the effect gained by the water droplets turning to steam within the fire gas plume.

However, Cold Cut Systems have been looking at more cost effective ways of both demonstrating Cobra and evaluating it against the types of firefighting risks that our customers (predominantly Fire and Rescue Services) want to protect Firefighters from.

To that end, we have been working closely with West Midlands Fire and Rescue Service (WMFRS), firstly to understand their risks, their response model and their success criteria and then to offer them the opportunity to evaluate Cobra UHPL as a risk mitigation tool. In undertaking this, we make it clear that Cobra is a tool in the modern-day Firefighters’ toolbox and it can be used to great effect in conjunction with other tools to enhance Firefighter safety as well as reduce water consumption and water damage. However it will not do everything and its effectiveness is, in many ways, down to the knowledge skills and attitudes of the operators/crews.

The Evaluation

We undertook these evaluations at WMFRS’ Oldbury Training Centre – an excellent training facility where a significant range of fire conditions can be created in firehouses rather than in fire behaviour containers. Oldbury has very accurate and reliable temperature monitoring facilities for the safety of site users, and these were used during the evaluations as a means of measuring the effect of firefighting using the Cobra Method.

Initially, we ran some initial evaluations on ventilated and under ventilated compartment fires as well as a high rise fire scenario where Cobra was used from an aerial appliance cage to very good effect.

We wanted to give Cobra a bit more of a test and broaden our own understanding of what it can do so we decided to evaluate Cobra on a simulated wind driven fire. A wind driven fire is described in UK National Operational Guidance (NOG) as:

”….one where external wind or ventilation-forced pressure causes strong air movements, affecting the severity of firespread.”

Whilst wind driven fires can occur anywhere where there is a strong prevailing wind, they are particularly hazardous when they occur in high rise buildings. Many firefighters will have experienced the fierce fire spread at a high rise fire where an external window or opening has failed allowing the wind to blow into the fire compartment. These conditions are very hazardous for firefighters and the advice from the National Institute for Science and Technology (NIST) in the USA is:

”…. in a wind-driven fire, it is most important to use the wind to your advantage and attack the fire from the upwind side of the structure, especially if the upwind side is the burned side. Interior operations need to be aware of potentially rapidly changing conditions.”

We felt that Cobra could be used to good effect on a wind driven fire as a means for facilitating a window of opportunity for Firefighters to enter the fire compartment under safer conditions.

We planned the event with WMFRS carefully, undertaking site visits as well as individual and joint risk assessments and ensuring that we had plans in place to deal with any emergency situations that might arise for real on the day. Safety crews and radio communications were all in place and tested before the evaluation commenced.

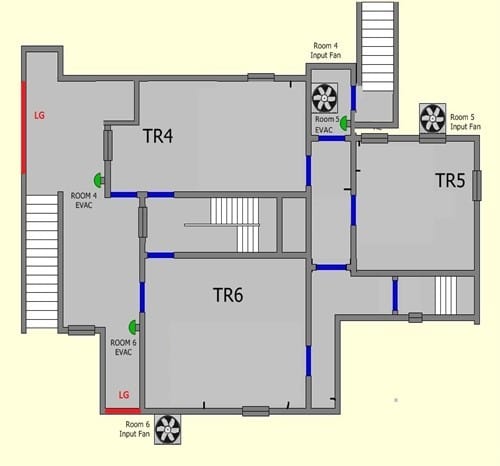

As can be seen from the picture below (figure 1), the wind driven fire was created using a PPV fan through a window into a fire compartment. Figure 2 shows the floor plan for the top floor of the firehouse. The window in TR6 was open to allow an outlet (exhaust) for the fire gases, (as shown by the red arrows). The firefighting crew, supplied by Cold Cut Systems, consisted of one Cobra Operator and one Cobra Senior Instructor with a further Cobra Operator acting as Cobra pump operator.

The fire compartment was room TR5 on the floor plan below (figure 2) with the fan going in through the window to the right of the compartment as you look at it on the plan. (Pale blue arrow)

The crew undertook a scan using a thermal imaging camera (TIC) before entering the building and decided to attack the fire using Cobra from the staircase adjacent to room TR5 (see the yellow arrow which is the Cobra access point on the plan at Figure 2). This gave the crew a high level of protection from the severe heat from the fire which was measured at 581 degrees centigrade before Cobra was used. It also gave protection against contamination from the fire gases and products of combustion. As can be seen from the temperature graph below, the temperature drop was quite dramatic going down to around 280 degrees quite quickly before briefly increasing and then dropping down to roughly around 160 degrees – a much better temperature to enter in order to fully extinguish the fire. It was interesting to note also, the change in temperature in the adjacent room (TR4) which showed a very similar temperature pattern to the fire compartment. The layout of the building offered few opportunities for a safe internal attack on this fire away from the flow path of the super-heated gases. Cobra was used for around eight minutes in total (including piercing) giving total water used at around 480 litres.

There were two key reasons for the success of Cobra in this scenario – firstly the skill and knowledge of the Cobra Senior Instructor and Cobra Operator which was used to good effect in deciding where to make the attack. Secondly, the over-pressurisation of the compartment as the water mist turned to steam – this worked well against the wind to allow the water mist to stay in the compartment for longer and so effectively cool the fire gases rather than being forced out along the flow path.

Please see the temperature readouts from the first floor rooms – Figures 3, 4 & 5 for details. Please note that there is an acknowledged discrepancy in the timings for the temperature readings, however the actual temperatures within the rooms were accurately measured.

The Cobra crew came out of the building and closed down their BA sets, they were able to report that they had not had to work in any high temperatures or in the presence of smoke/fire gases.

If you would like to discuss this article further or if you require further information on Cobra Ultra High Pressure Lance firefighting equipment, please contact Bernie Higgins on [email protected]

This article was originally published in the November edition of IFSJ. To read your FREE digital copy, click here.