IFSJ Exclusive: Know your viscosity with FIREMIKS

- January 10, 2023

- 9:26 am

Iain Hoey

Share this content

Per Aredal International Sales Director at FIREMIKS AB, sheds light on the proportioning systems suitable for the transition to synthetic fluorine-free foam

During the market transition from AFFF (Aqueous Film Forming Foam) to SFFF (Synthetic Fluorine Free Foam) concentrates it is important to know the viscosity of the SFFF concentrate to choose the right type of proportioner.

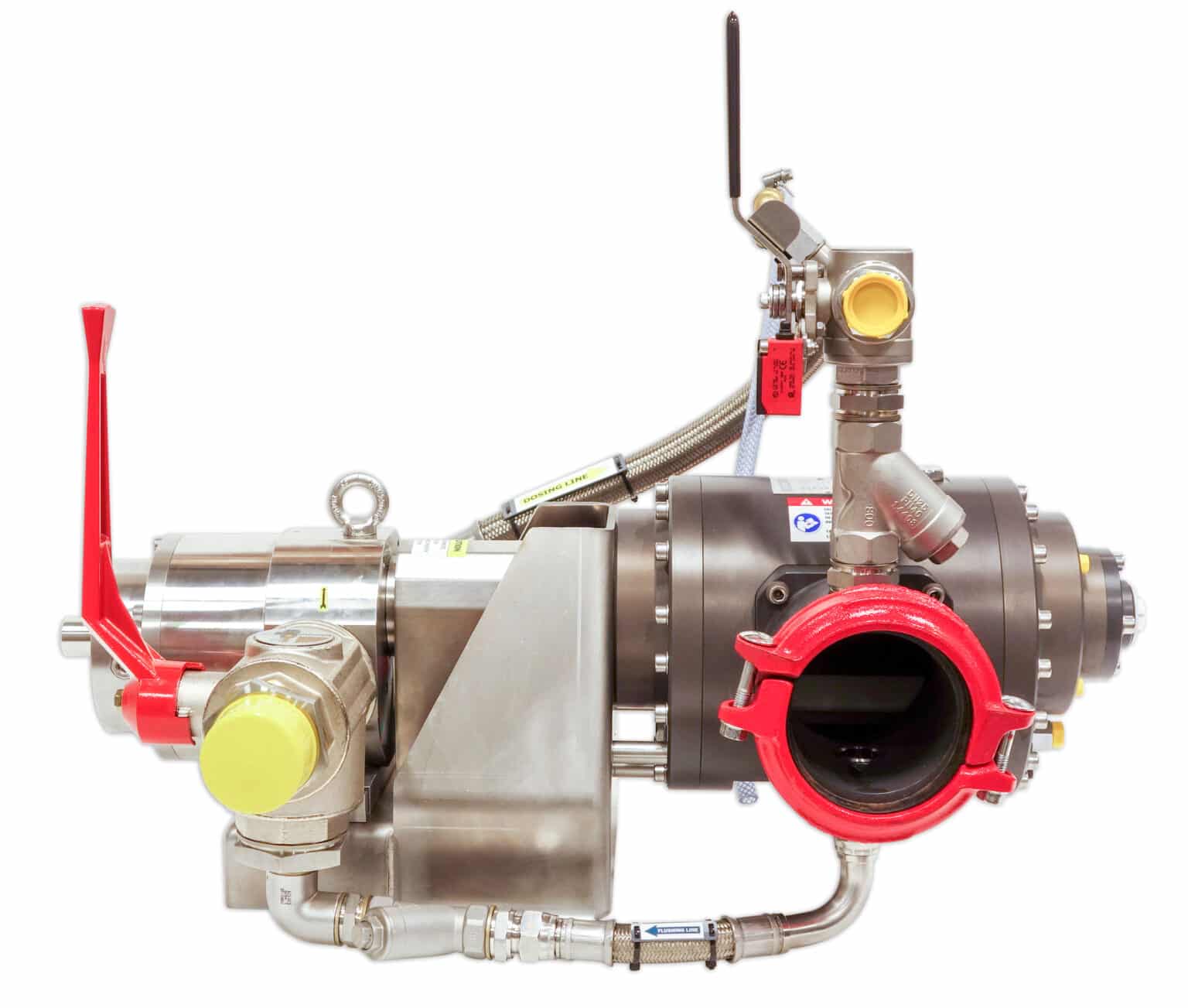

FIREMIKS is a water driven volumetric pump proportioner for firefighting – for fixed installations connected to a concentrate tank with gravity feed to the dosing pump. Extinguishing water drives the volumetric water motor, which in its turn drives the positive displacement pump that doses the correct amount of concentrate in the extinguishing water exiting the water motor.

As the regulatory authorities now are pushing for soonest possible transformation from PFAS-containing concentrates, towards SFFF concentrates, many proportioning systems are re-evaluated to ensure compatibility with the new concentrates. Different concentrate manufacturers offer a variety of foams which comes in a wide range of viscosities, including very high viscous concentrates. To be able to select an appropriate proportioner one needs to know the properties of the concentrate.

FIREMIKS is uniquely positioned to offer two types of dosing pumps, Gear and Piston (plunger), combined with our sturdy multi-vane motor that offers optimal reliability based on +30 years of experience in the market. Among several important factors, besides flows and pressures, we always gather info from the customer regarding the concentrate type and viscosity before we propose which type of pump that will match the customers need.

Proportioners with Gear Pump

Water motor driven pump proportioner equipped with a Gear pump are particularly suited for operating in the higher range of a systems maximum flow rate, such as deluge and large fire monitor systems. They are also most suited for high and very-high viscosity concentrates.

For example, we have with excellent result tested one of our Gear pumps models with a Fluorine-free foam with 8,040 cP (Brookfield Viscometer Spindle #4 at 30 rpm). The reason Gear pumps works well with these very-high viscous concentrates is that they are equipped with counter rotating gears which seals better with high viscosity fluids and creates an even flow that does not agitate the concentrate.

Proportioners with Piston Pump

Water motor driven pump proportioners equipped with Piston (plunger) pumps are on the other hand particularly suited for use in systems with low start-up flows in relation to the systems maximum flow rate, for example sprinkler systems. They are also very suited for low and medium viscosity concentrates.

Important to know is that Piston pumps have a limit upwards to high viscosity concentrates, normally around 4,000-4,500 cP (Brookfield Viscometer Spindle #4 at 30 rpm) due to the Piston pump reciprocating principle; for each revolution, the plunger sucks concentrate and then presses it out and the concentrate goes from zero to full speed twice per revolution in a very tight pump design. If the static viscosity is too high with non-Newtonian concentrates, the concentrate will not flow smoothly and therefor the correct dosing rate might not be achieved.

Important for all systems is that one should ensure that diameter on the foam supply piping is large enough for the concentrate delivery and to avoid longer concentrate lines. Recommendations are specified in our data sheet for each model. We are always available to guide you with more specific recommendations if needed for your specific project.

Verifying dosing rate according to EN 13565-1, NFPA 11 and FM 5130 on water driven volumetric pump proportioners.

To measure and verify the dosing rate on a proportioning system according to regulations and standards, at the commissioning and yearly maintenance, is an important task. The aim is to ensure that the installed firefighting system proportion the correct amount of the concentrate into the firefighting water flow, as intended and designed.

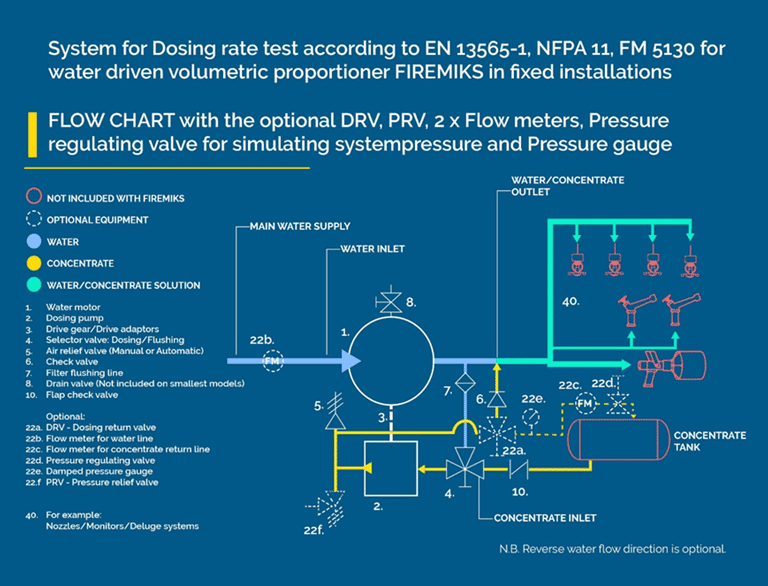

To be able to easily test and verify the correct proportioning the FIREMIKS unit needs to be equipped with an optional Dosing return valve (DRV) (no 22a.) that directs the concentrate back to tank instead of being induced into the water flow. This allows for testing the system without mixing the concentrate. A Pressure relief valve (PRV), (no 22f.) is included with the DRV to eliminate the risk for over-pressure if return line to tank is closed/blocked by mistake.

Furthermore, one needs to install two calibrated Flow meters; one for main water line (22b.) and one electromagneticflow meter for concentrate return line (22c.), combined with a Pressure regulating valve (or a regular valve which can be partly closed to regulate the backpressure, e.g. globe valve) (22d.) to simulate system pressure, displayed by a Pressure gauge (22e.).

Environmentally and economically beneficial testing system

This described dosing test system ensures that it is possible to practise and test dosing rate without consuming the concentrate. It gives also substantial savings over the years with no cost for cleaning or destruction of dispersed solution after the test. With the growing strict environmental regulations, this advantage has become even more important today.

The accurate way of verifying dosing rate

Verifying dosing rate equals to verifying the correct volumetric function of both the water motor and dosing pump with two independent calibrated flow meters and calculate to this formula, in accordance with EN 13565-1, NFPA 11, FM 5130:

(Concentrate flow) / (Water flow + Concentrate flow ) x 100 = Dosing rate %

Revolution counter method – the limits

The revolution counter method which is also presented on the market assumes the correct working of the water motor, this means it gives only an estimateof water flow.

The is not an approved method to verify dosing rate as described by

EN 13565-1, NFPA 11 and FM 5130, who each require the use of a separate flow meter to measure water flow. Quote from FM Approval guide ref. rpm method: “May be used to provide a general estimate of the extinguish water flow”.

Revolution counting with handheld tachometer

The estimated water flow can also be measured with handheld tachometer (contact or non-contact) to ensure that the unit is not over-speeding, i.e. working within the upper rpm = flow limit specified in the Data sheets of each FIREMIKS model.

Measuring concentrate flow

An alternative method to measure the pumped concentrate is to pass it into a separate container after the pressure regulating valve (22d) and weigh the amount used from the tank during a defined time and then converting it to the corresponding flow rate.

In our experience, magnetic flow meters work well for measuring concentrate flows. Even so, it is even better to be able to establish a known weight or volume of concentrate used in a known time interval, because even approved magnetic flow meters are not tested on all concentrates available.

Handling and monitoring on site or remote

The flow meters, valves and pressure gauge described above can either be handled, monitored and read on site, or connected to remote handling, monitoring and readings. Independently of this – the most important factor is to ensure that data is measured accurately and according to standards to ensure that the installed firefighting system proportions the correct amount of the concentrate into the firefighting water flow.

This article was originally published in the January edition of IFSJ. To read your FREE digital copy, click here.