IFSJ Exclusive: Thermal Imaging Camera use for Hazmat

- April 26, 2023

- 2:34 pm

Iain Hoey

Share this content

Gavin Parker, Senior Station Officer with Fire Rescue Victoria, looks at using thermal imaging cameras in Hazmat incidents

While Thermal Imaging Cameras (TICs) are commonly used for fires, they can also be used for Hazmat incidents providing information without contact of the product or substance that may otherwise be unavailable visually.

Some cameras are intrinsically safe and may have operating modes, features and functions suited to Hazmat use. An understanding of image interpretation and application of a TIC for hazmat incidents and their limitations is important to optimise the equipment’s use.

Hazmat incident analysis

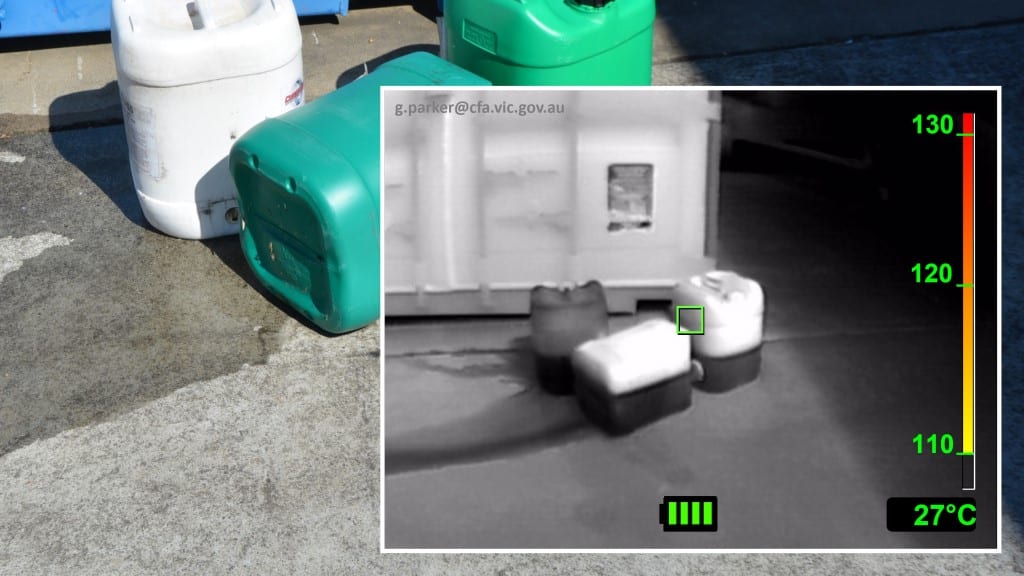

TICs can identify slight energy differences, presented in shades of grey and in some cases a hazmat specific colour palette selection that indicates surface energy variation at a fraction of a degree. Most fire service cameras can also display temperature differences with Direct Temperature Measurement (DTM) in 1° increments.

Typically, with camera use at fires, conditions may change rapidly requiring an extremely quick interpretation of the image and a fast-decision-making process using qualitative assessment that provides visual cues.

During hazmat incidents we may be able to make a detailed study of the scene. Observations can be done utilising comparative and trending assessment, quantitative and qualitative methods, using typically passive and sometimes active methods of detection.

Passive detection can be achieved when there is thermal contrast between the object of interest and its surroundings. An example of an active method could be external surface cooling to increase thermal contrast using a spray of water on objects such as containers to cool the airspace to indicate the product level.

The image and DTM of the object can be done from several viewing angles, utilising and comparing available operating modes. Baseline knowledge of the scene can also be used. As with all TIC use, when visible light is available, compare and consider what is detected in Infrared (IR) with what can be identified visually, together with other known information.

Uses and features

Generally, the use of TICs at Hazmat incidents falls into obtaining information for the following tasks: identifying product levels in containers; location and spread of spills and leaks; and monitoring chemical and physical change.

Features and functions that can be utilised for Hazmat incidents can include: intrinsic safety as not all cameras are intrinsically safe, labelling for intrinsic safety and certification will be located on the camera; DTM which allows for spot temperature measurement within the limitations of the cameras Distance to Spot ratio (D:S); and image freeze – to capture the image for detailed examination or to move to a shaded area to view without the effects from screen glare.

Other functions include: image capture and video recording and playback to record and on some cameras view previously recorded images/footage; laser pointer to indicate the centre of the field of view, as well as the location to others of product levels, extent or outline of leaks and spills; and tripod mount to enable the camera to be fitted to a standard camera tripod for hands free use.

In addition: a visual sensor may allow a visual image and video capture, or the blending, edge definition or overlay of a thermal over a visual image; digital zoom can be utilised for viewing from a safe distance, improve accuracy of DTM and to reduce the field of view to manipulate the image to reduce or limit background energy dominating the image; hot and cold spot tracker displays a floating curser that automatically indicates the hottest or coldest item within the field of view and can be used to identify the source of some gas leaks and chemical reactions; and user selected cameras modes and screen palettes provide flexibility in detection and screen display options, particularly in low thermal contrast situations.

Screen palette selection

The choice between viewing in standard mode or other available modes will depend on a number of factors and each has its own strengths and weaknesses.

White hot (standard mode) is the more commonly used palette. White hot displays warmer objects in lighter shades and cooler objects darker. Grayscale palettes offer simplicity for scenes with a high thermal contrast and generate images with realistic details.

User adjustable screen temperature colourisation or isotherm allows the operator to select the point at which screen temperature colourisation occurs usually a single bright colour; this can be a useful feature when a leak or product level in a container is expected to be in thermal contrast with the container or environment. If there is low thermal contrast it may be difficult to set the camera without it being oversaturated with colorisation.

Hazmat or colour screen palettes can be suited for leaks, spills and determining product levels when focusing on an area with low thermal contrast. This may allow the colour palette to indicate slight temperature variations. For fire use a full colour pallet may overwhelm and confuse us with information, but when used in a hazmat application it can be suited for scenes with minimal energy differences.

Reverse polarity of greyscale (black hot) may have benefits under some circumstances, particularly in cooler outdoor environments.

Temperature measurement

Be aware of the limitations of DTM. These readings can be falsely high or low, the magnitude of error can range from a few degrees to a significant error. Factors influencing temperature measurement includes; size of the area being measured and distance from the target, background energy, atmospheric conditions, limitations of the equipment, the condition and emissivity of the surface.

The emissivity of surfaces will impact the apparent temperature or how it appears and the DTM; particularly gloss painted, stainless steel or other shiny metals and finishes. Shiny surfaces with low emissivity may reflect background energy levels. This can produce an inaccurate image and DTM that can be falsely interpreted.

General limitations using a TIC during Hazmat

Limitations include, by are not limited to the following: TICs will only identify surface energy and temperature; product levels in containers can only be determined with solids and liquids, not gases; product levels, leaks, spills, and reactions may not always be able to be identified or determined; environmental factors such as sunshine or other radiant heat may give a “false” thermal indication on surfaces by either reflection or absorption of energy; cold celestial radiation from either the day or night sky may also be reflected off shinny surfaces; and some vapour clouds near the source of a leak may be able to be identified but gas leaks may not.

Other limitation include: screen glare during outside use will sometimes make it difficult to clearly see the image displayed on the viewing screen – some cameras have accessory screen shrouds, otherwise shielding it with a hand or the use of a towel or jacket may cut down screen glare (alternatively, use the “image freeze” or capture function if available and view the screen in a shaded area); low sensor resolution and a lack of some specialist features and functions may limit the equipment’s suitability for hazmat applications; and finally not all TICs are intrinsically safe, and do not change batteries, or add powered accessory items to the TIC in a flammable atmosphere.

Decontamination and cleaning

Manufactures may list environmental and corrosion test standards in the equipment’s specifications. For decontamination, follow agency procedures and instructions in the camera’s operating manual for after use maintenance and cleaning.

A thermal imaging camera can provide information at hazardous materials incidents that may otherwise be unavailable. This can be gathered from a distance, increasing the safety of personnel.

It is important to remember that the information provided may not always be definitive and should be verified by other means if possible. Follow standard procedures and use in conjunction with PPE/PPC and other standard equipment. Experience, training, an understanding of the basics of thermal imaging and the camera you are using is critical in the effective and successful use and interpretation of images at hazmat incidents.

The views expressed are that of the author and not necessarily that of CFA or FRV.