Proportioning precision

- January 9, 2024

- 9:13 am

Iain Hoey

Share this content

Per Aredal, International Sales Director at FIREMIKS AB, discusses the advantages of water driven variable viscosity proportioners

The current shift in the market from AFFF (Aqueous Film Forming Foam) to SFFF (Synthetic Fluorine-Free Foam) concentrates poses challenges for both existing and new foam systems.

One critical aspect is the proportioning in a firefighting solution, where understanding the viscosity of the new SFFF concentrates is key in selecting the appropriate proportioner.

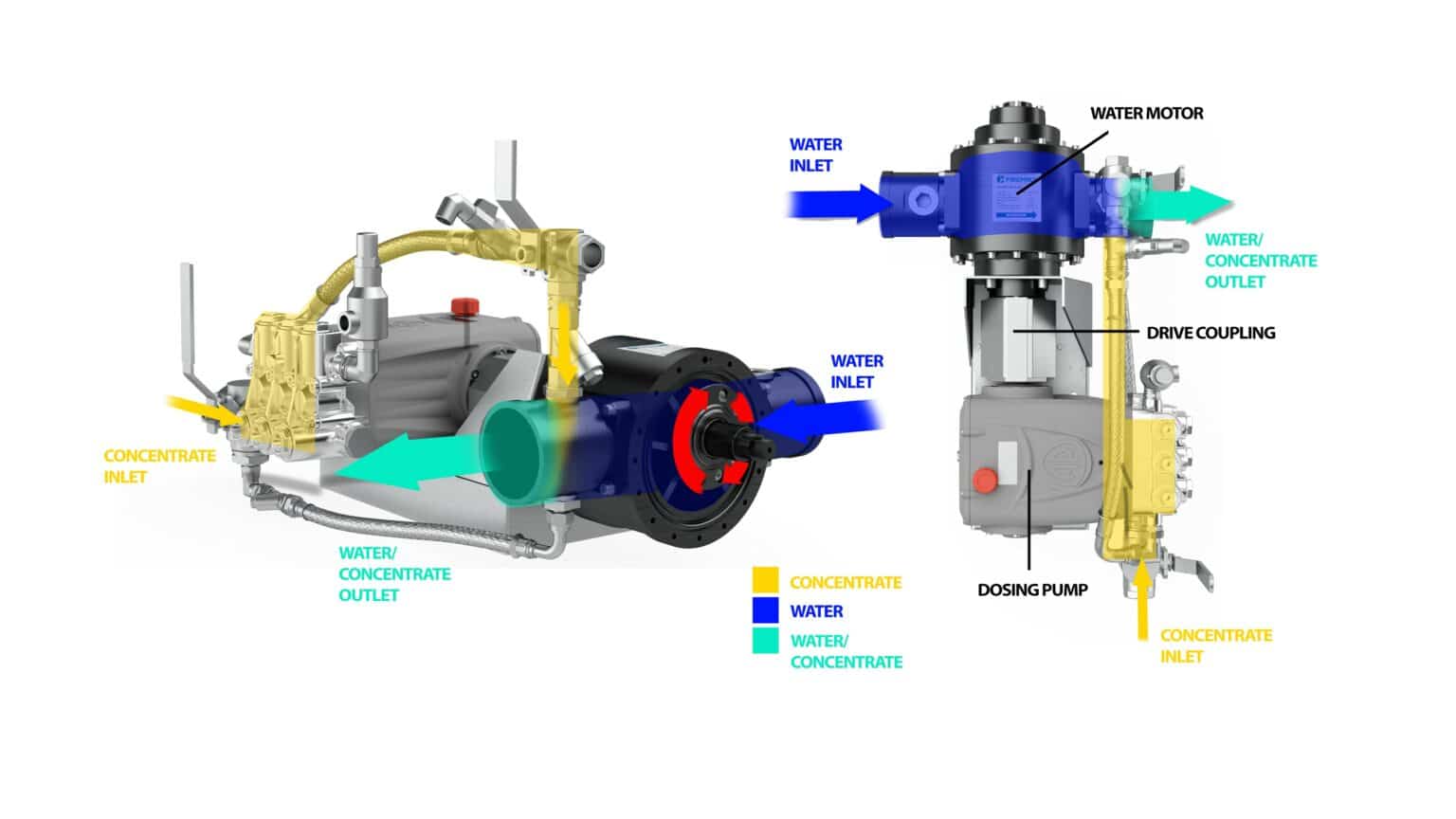

The FIREMIKS concept is a water-driven volumetric pump proportioner designed for fixed installations, connected to an atmospheric concentrate tank with gravity feed to the dosing pump.

The system requires solely the extinguishing water to power a volumetric water motor, which, in turn, operates a positive displacement pump.

This pump accurately doses the required concentrate into the extinguishing water across a broad flow and pressure range.

Notably, no additional energy source is necessary for its operation.

Regulatory bodies are driving the shift from PFAS-containing concentrates to SFFF concentrates, prompting a reassessment of many proportioning systems for compatibility.

Various manufacturers offer SFFF foams with a wide range of viscosities, including very high-viscosity concentrates.

To select an appropriate proportioner, understanding the concentrate’s properties—whether it falls within a viscosity range of 1cP to around 5-6000 cP (measured using a Brookfield Viscometer Spindle #4 at 30 rpm)—or if it’s classified as very high viscosity is crucial.

FIREMIKS stands out by offering two types of dosing pumps—Piston and Gear pumps—alongside a robust multi-vane motor based on over 30 years of market experience.

When working with clients, apart from considering flows and pressures, we prioritize understanding the concentrate type and viscosity, a quite complicated subject, before recommending the suitable pump type.

Piston Pump Proportioners

Our models equipped with Piston pumps are classified as “Variable viscosity proportioners” in FM approval terminology.

They maintain precise dosing rates within approved tolerances across a broad viscosity spectrum—from low viscosity to around 5-6000 cP (dependent on variables like temperature, concentrate type and brand).

Important to know is that all Piston pumps systems on the market have a limit upwards on handling viscosity concentrates, due to the Piston pump reciprocating principle; for each revolution, the plunger sucks concentrate and then presses it out and the concentrate goes from zero to full speed twice per revolution.

If the static viscosity is too high with non-Newtonian concentrates, the concentrate might not flow smoothly and therefore the correct dosing rate may not be achieved.

Typically, our Piston pump models excel in systems with low start-up flows relative to the maximum flow rate, ideal for applications like sprinkler systems, providing versatility across a wide flow range.

Water motor-driven pump proportioners equipped with Gear pumps are well-suited for handling high and very-high viscosity concentrates.

We have successfully tested Gear pump models using Fluorine-free foams with a viscosity of up to 8,040 cP (Brookfield Viscometer Spindle #4 at 30 rpm).

Gear pumps excel with high-viscosity fluids due to their counter-rotating gears that create a consistent, non-agitating flow, ensuring effective sealing with such fluids.

Our Gear pump models are particularly efficient in applications operating at the higher end of the maximum flow rate, such as deluge and large fire monitor systems.

For all systems dealing with higher viscosity concentrates, ensuring adequate foam supply pipe diameter, good gravity feed, and minimizing concentrate line lengths are crucial.

Our datasheets specify recommendations, and we’re available for more tailored guidance for your project.

Catering to any flow size

FIREMIKS offers a diverse range of models catering to various flow sizes and proportioning requirements.

Our smallest model has a max flow of 180 lpm and the largest single model a capacity of 10000 lpm flow.

To achieve larger flows, up to 20000 lpm, we offer parallel installed FIREMIKS, on a base skid or mounted as” double-deckers”.

Our three standard models are: 12000 lpm (2 x 6000 lpm), 16000 lpm (2 x 8000 lpm) and 20000 lpm (2 x 10000 lpm).

For fixed proportioning we offer 1% and 3% as standard.

We may also supply units with special dosing rates, for example 0,1%, 0,3% 0,5%, 2%, 2,75% and 6%, on customer’s request.

Models with selectable proportioning are available with 0,3-0,6-1% and 1-2-3% (For selected flow sizes 0,5-1-3%).

Economical and environmentally beneficial testing with FIREMIKS is easy with optional Dosing/Return valve (DRV) and two separate flow meters.

If requested we may offer a complete dosing rate testing system that follows the guidance of EN 13565-1, NFPA11 and FM 5130.

Advantages of FIREMIKS Variable viscosity proportioners over Bladder tank systems

FIREMIKS ensures an uninterrupted foam supply as long as water and concentrate are available.

Adding more concentrate is as simple as connecting another container/drum.

In contrast, Bladder tank systems experience downtime when the bladder needs refilling.

As a Variable viscosity proportioner FIREMIKS Piston pump models handles concentrates from 1 cP (like wetting agents) up to around 5-6000 cP without the need of calibration.

A Bladder tank system is often designed for one specific concentrate viscosity and needs to be recalibrated and balanced to fit a new concentrate with another viscosity, adding crucial down-time for this replacement or recalibration.

To change foam type or brand concentrate, including to another viscosity is also a simple task with FIREMIKS if an IBC-container is used as foam concentrate supply, just exchange the IBC-container to another with the new/other concentrate within the approved range.

In comparison, to exchange foam concentrate in a rubber bladder may be a challenging task, including cleaning or replacement of the bladder.

In summary the FIREMIKS-system is a straight-forward system, easy to understand and to install, handle, maintain and test.

About the author

Per Aredal is International Sales Director at Firemiks AB, with + 30 years of experience of producing and delivering water driven volumetric pump proportioners worldwide.

For more information contact Per at [email protected], on mobile: +46-76-139 70 34.

For more information, go to www.firemiks.com.