Exclusive: Keeping fire suppression in proportion

- October 17, 2022

- 12:27 pm

Iain Hoey

Share this content

IFSJ sat down with Frank Preiss, Managing Director at FireDos GmbH, to discuss the development of proportioning systems and extinguishing monitors for fire suppression

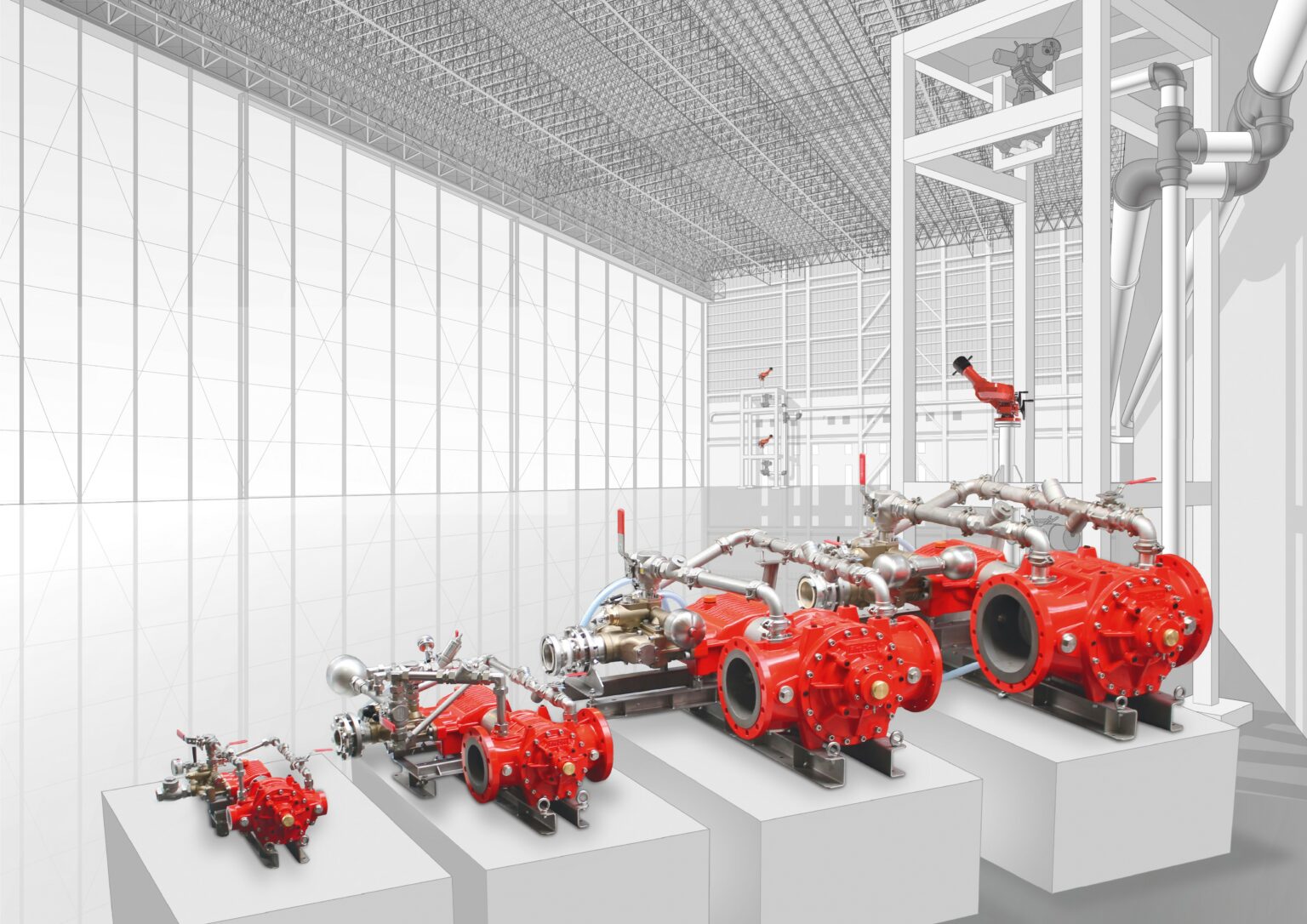

Over twenty years ago, FireDos developed and established the proportioning concept consisting of a water motor and piston pump and with it the environmentally friendly and cost-effective testing of the proportioning rate, without the production of foam or premix. Since then, it has delivered more than 14,000 units to municipalities and industrial customers around the world.

In 1979 the technology was initially developed and used in industrial dosing systems. In 1994, the first proportioners were used by fire brigades. In the following year the proportioners were optimised for use for stationary fire protection. In 2013 FireDos made the decision to expand the product portfolio and a range for fire extinguishing monitors was developed. The focus was put on big flow volumes, extended reach, and remote control, but product for mechanical operation with small water flows are available.

“Our focus is on customer service, including technical training and quick response to any industry inquiries,” says Frank Preiss, Managing Director at FireDos. “We have the products certified by globally recognised institution such as FM Approvals and VdS and are certified according to ISO 9001 (Quality Management System) and 140001 (Environmental Management System). All of the systems that leave our plant have been 100% tested over the complete operating range at our state-of-the-art test bench.”

Proportioning systems

Foam, says Preiss, has proven to be the best medium to extinguish fluid fires. It consists of water, foam concentrate and air. The foam concentrate is mixed with the extinguishing water at a precisely defined rate. Air is then added to this premix to generate the foam.

NFPA 11, a standard written be the internationally recognised US National Fire Protection Association, describes various types of foam concentrate proportioning equipment. There are three technologies that are most commonly used: the bladder tank in combination with mainly venturi proportioners, the driven proportioning pumps with flow meter and the water motor with proportioning pump.

Preiss says that whilst there are various differences and advantages and disadvantages for all technologies, tight limits for the proportioning of foam concentrate apply to all of them. He explains: “The proportioning rate must not be less than the permitted values – i.e. 3% for a 3% foam concentrate or 6% for a 6% foam concentrate.

“The proportioning rate must not exceed 30% or an absolute maximum of 1% above the permitted value i.e. 3,9% for a 3% foam concentrate or 7,0% for a 6% foam concentrate. And to guarantee correct proportioning, the proportioner, including the proportioning rate must be tested at least once per year and its correct functioning must be checked.”

FireDos has decided to focus on water motors with proportioning pumps, Preiss tells. “We have engineered a proportioning system specifically for firefighting foams. All other technologies are using pumps that have been designed for various liquids, but we see that with our in-house developed and optimised water motor coupled with a piston pump specifically designed for foam concentrates we get the best results over a wide range of foam concentrate viscosities and operating ranges.

“The operating ranges being system pressures and extinguishing water flow rates. In addition, the system is purely mechanical, and the proportioning rate can be tested without creating foam or premix. This is cost-effective and eco-friendly.”

When selecting a proportioning system, Preiss advises first to decide on what foam concentrate to use. Once this has been decided the suitable fire protection concept, including alternative scenarios, must be developed. Only then, he says, should the decision be made on which proportioning system is to be used.

Extinguishing monitors

Extinguishing systems typically consist of a fire pump, a proportioning system and tank for the foam concentrate, discharge devices such as foam nozzles, sprinklers, foam pipes or fire monitors and the corresponding piping.

Firefighting monitors are discharge devices mounted stationary on pillars or towers or mobile on vehicles or trailers and available in many sizes. They are suitable to discharge water to extinguish regular class A (solid combustible materials) fires or foam, e.g., to extinguish flammable liquids such as a surface fire in an oil storage tank. The extinguishing agent flow rate can be over 50 000 l/min and the reach can be up to 180m if the pressure of the fire pumps is sufficient.

The main advantage of using firefighting monitors, says Preiss, is their ability to allow you to place the water or foam on a specific location, opposed to fixed extinguishing systems such as sprinklers, that can only act in their immediate vicinity. In addition, they have far throwing ranges that allow the firefighting personnel to stay outside of danger zones.

The most important consideration, he says, is the question on what must be protected and what functionality is necessary to do this: “Here the minimum and maximum water flow and the maximum required throwing range are important factors.

“For this the available maximum pressure of the fire pump, the pressure drop of the hose system and the pressure drop within the monitor is essential. Here FireDos is especially proud to have engineered their fire monitors using special hydrodynamic modelling that resulted in the innovative, flow-optimised ‘Oval Flat Design’, that ensures minimum pressure loss which in return guarantees maximum throwing ranges.”

Since the introduction of the FireDos proportioning technology over 14,000 units have been installed in over 45 countries worldwide. The installations range from small proportioning systems with a maximum water flow of 500 l/min protecting facilities such as a distillery to an installation with 5 pieces of FireDos FD20000 with a combined flow of up to 100,000 l/min protecting the tank farm of an international airport.

Recently, the company installed its biggest proportioner, an FD25000, in a Methanol plant in the US. Elsewhere for a project in the Middle East at an oil storage facility it supplied the proportioners and firefighting monitors for a mobile extinguishing system.

In recent years, Preiss says he has seen an increasing number of customers combining the FireDos proportioners and firefighting monitors as well as an increase in the quantity of remote-controlled monitors coupled with heat detection systems.

“The early fire detection system allows the full-surface monitoring of large areas using panoramic thermal imaging,” he says. “Combined with intelligent analysing software, this enables the precise localisation of a fire source. The remote-controlled FireDos monitors can then be automatically activated and used for pinpointed extinguishing of a hot spot with water or foam. This reduces the damage a fire can do and helps avoid lengthy and costly system downtime and collateral damage with little effort.”

What’s next for fire protection?

Preiss says that FireDos is seeing is a continued demand for quality extinguishing components and systems: “The industry has seen a lot of fires over the last years that have sensitised the awareness for the need of functioning and reliable fire extinguishing technology. We are also seeing a drive in the recycling and waste management facilities towards modern technology.

“In addition, the transition in a lot of countries from older, fluorine containing foam concentrates to new fluorine free and more environmentally friendly products has opened the door for rethinking the technology that has been used to date.

“Firefighting is essential for all industrial applications, and we anticipate seeing a continued demand for our technology. It will though remain to be seen if we will have a global recession in 2023 and what effect this will have on all safety related installations.”

For FireDos, Preiss says they will continue to be a world class leader in the development and production of innovative and reliable proportioning systems, extinguishing monitors and trailers for firefighting. The company will concentrate on two product lines: “For one the enhancement of our remote-controlled monitor technology in combination with early fire detection and the improvement of automatic fire extinguishing and for the other the expansion of our smart proportioning technology.

“This will allow remote monitoring of our mechanical proportioners to optimise the maintenance process through predictive analysis, allow remote troubleshooting and ultimately increase the equipment reliability and reduce costs.”