Why heat and overheat detectors are vital for industrial and hazardous areas

- July 7, 2022

- 7:30 am

Iain Hoey

Share this content

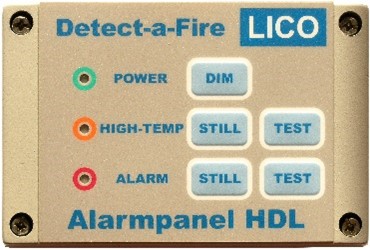

Smoke and fire detectors are an industry standard when it comes to raising the alarm but often by the time they register an outbreak it might already be too late. This is why manufactures of active fire detection systems such as LICO have developed technology that can recognise heat and overheat before it becomes a bigger problem.

Avoiding ignition

Generally in the case of a smoke or fire, a fire security system will alarm any personnel in the proximity allowing them to act, whether this is to extinguish the fire or evacuate the premises and contact the local fire department. The situations in which fire teams are called out are normally, however, the worst-case scenario for when the fire has already taken hold. The preferable scenario is one in which more human lives are saved. The time it takes to mitigate any hazard can be vastly reduced if more focus is put into early heat and overheat detection to prevent a fire or explosion.

Excessive heat, even without the presence of smoke, can be a potential hazard of fire or explosion. The prevention of a potential fire, caused by excessive heat, allows corrective action to avoid igniting flames. Active fire protection expert and heat detector unit manufacturer LICO has several solutions in its wide range of fire prevention devices to ensure early detection.

HDL (Heat Detectors LICO) products are custom made with the customer and/or with the local system integrator. Its devices are designed to cover a wide range of industrial use including: engine rooms, transformer stations, wind generators, saunas, kitchens, painting rooms, gas turbines, off-shore platforms, oil refineries, and nuclear power plants. All HDLs have ATEX, EN 54-5, CE and ISO 9001 certificates to ensure they are the highest level of technical solutions.

A simple solution

“Our HDL heat- and overheat detectors are based on bimetallic, heat detector switches, free of electronics, to provide the best reliability in high temperature applications, also during harsh environmental conditions,” says Gergely Böde, Sales & Production Manager at LICO. “Simplicity goes through the product family to provide easy installation and a cost-effective maintenance. Various alarm temperature settings are available from 140°F(60°C) until even 950°F(510°C) in N/O or N/C potential free contacts, which makes fast system integration in practically every already existing or new systems. “

The sensors in the HDL units are designed with rate compensation, providing a unique advantage over both fixed temperature and rate-of-rise types of detectors. They can accurately sense the surrounding air temperature regardless of the fire growth rate in contrast with fixed temperature detectors which must be completely heated to alarm temperature and therefore a lag in response time may occur with a fast rate of fire.

Böde adds: “Rate-of-rise devices, on the other hand, are triggered by the rate of increase in ambient temperature and are subject to false alarms caused by harmless, transient thermal gradients, such as the rush of warm air from process ovens.”

This article was originally published in the June edition of IFSJ. To read your FREE digital copy, click here